5 simultaneously working axes

In addition to the three linear axes in x, y and z, two rotary axes ensure many and varied machining options.

Rotation range up to ± 35 degrees

The B axis with its exceptional great rotation range makes the K5 ideal for model casts and surgical guides as well as prosthodontics and implantology.

Blanks of up to 40 mm thickness

K5 lets you machine a wide range of materials and indications: blanks and blocks of wax, plastics, model plaster, zirconium oxide and composites up to non-precious alloys on a cobalt-chrome basis.

Machine bed of massive aluminum cast

A cast body which is closed at five sides absorbs vibrations and ensures a high stability of the whole machine. Additionally reinforced linear guides in x, y and z, as well as a double mounted B axis, further increase the rigidity of the whole axis system – so that you’ll always get first-class milling results.

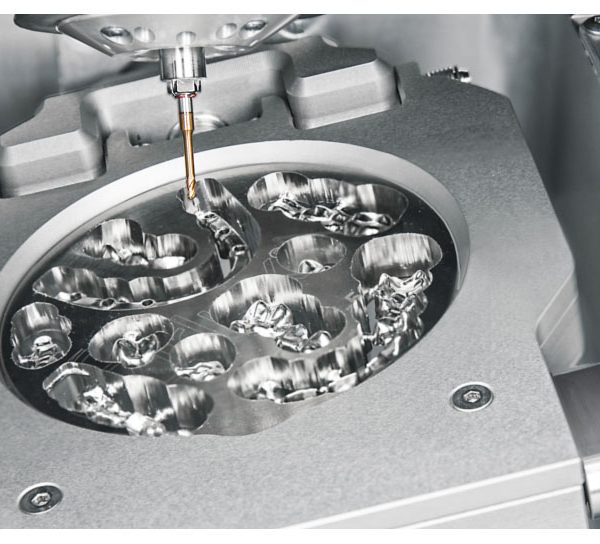

An automatic changer for 16 tools

In addition to the currently required tools, you can equip the tool changer with replacement tools right away. Thus you can continue working without interruption if a tool is worn out. Haptic tool measurement for usage of diamond-coated tools.

Powerful and highly precise synchronous spindle

With 4-fold hybrid ceramic ball bearings and a nominal power of 300 W under continuous load – well-balanced torque band.

Sophisticated protective mechanisms

Automatic safety interlock at the front cover while machining. The established working chamber sealing air concept in combination with a rubber gaiter effectively protects the mechanics, electronic and spindle against dust and chippings.

Practical drawer for accessories

Your tools and blanks are well stored and immediately at hand. The drawer also holds an integrated administrated tool board (ATB) for your milling tools. Its 30 numbered slots will be administrated by the DentalCAM software.