Intelligent, Unattended Milling

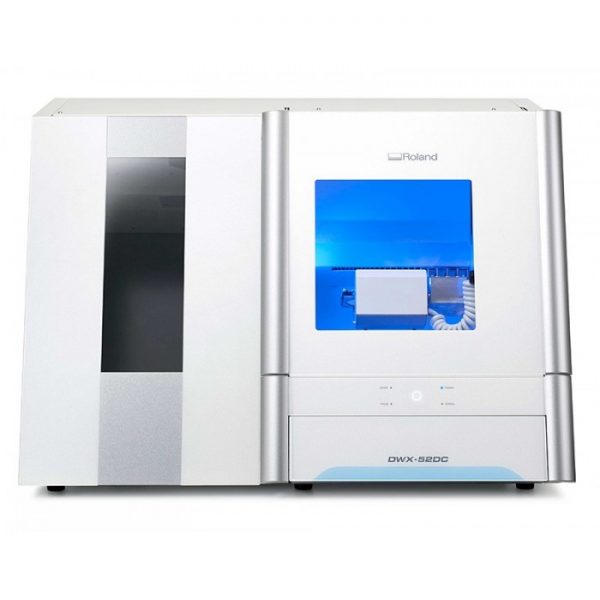

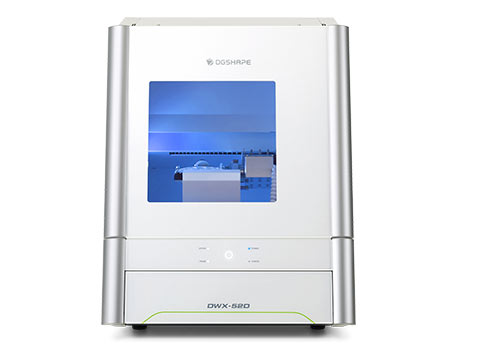

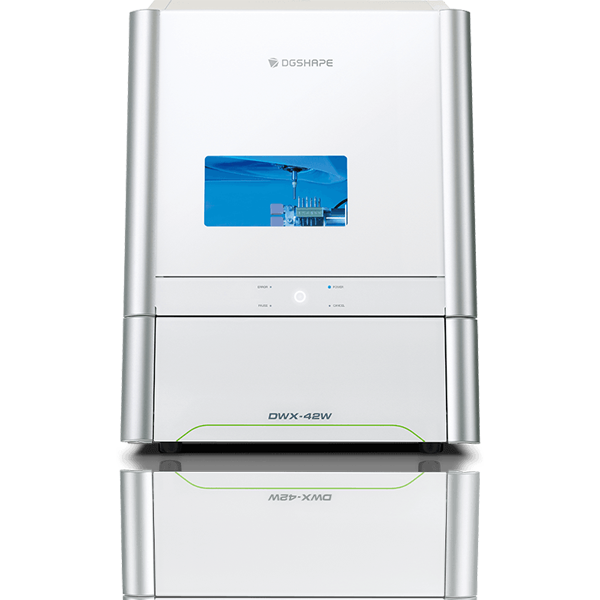

The DWX-52DCi dental milling machine now comes with performance visualization software and other intelligent updates. Power it on, let it go, and automatically mill numerous dental restoration jobs with complete unattended confidence.

Reliable Milling Now Comes with Upgraded Efficiency

DGSHAPE by Roland takes thirty-years of reliability and innovation and combines it with next-level production to meet the needs of today’s growing lab businesses. The new, upgraded DWX-52DCi dental mill features DWINDEX performance visualization software and an advanced dust collection system for a smart and clean operation.

Additional Features

Six Adapters Included

For an easy set-up and operation, right out-of-the-box

Intelligent Tool Changer (ITC)

Knows which tool to automatically swap out when tools have reached their designated lifespan

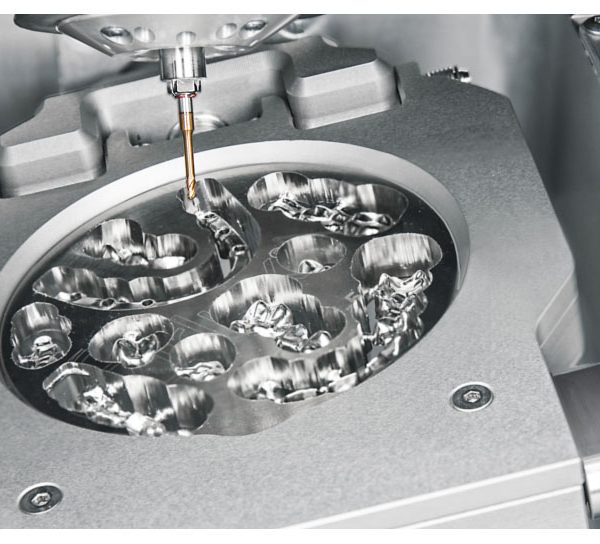

5-axis Milling

A smooth and steady ball screw-driven system provides superior milling results – simultaneously rotating and tilting discs for deep undercuts and also milling large arch restorations and other full-mouth prosthetics

Virtual Machine Panel (VPanel)

A user-friendly VPanel enables easy production and device monitoring – including advanced email notification

Ionizer

Reduce dust and static when working with PMMA

Clean Milling Environment

A powerful auto-on internal dust collection system and automatic cleaning brush ensure a clean milling environment

Air Pressure

Automatically changes air pressure based on the CAM material data

Additional Storage

Store tools, jigs, adapters and more in a handy, built-in storage draw